IPEC GLOBAL -

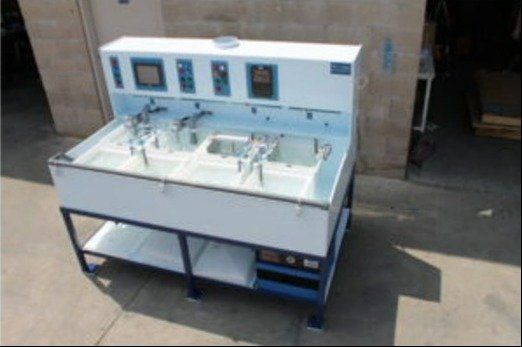

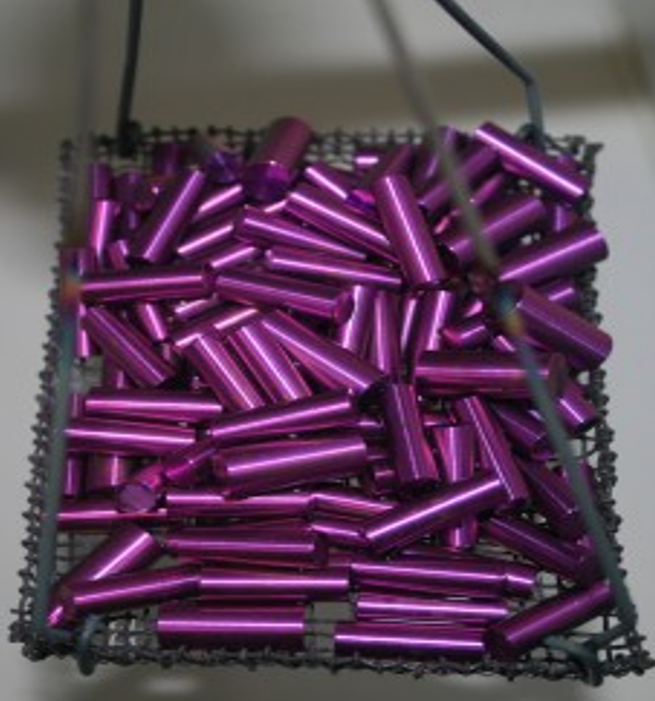

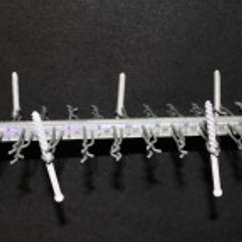

Titanium Anodizing Equipment

All the Titanium

anodizing equipment you need, in one place

We have what it takes to help you with your anodizing project

Multi-Etch

The Safer Way To Etch Titanium

Times and regulations have changed since we first started etching titanium in 1978. During our first experiments, while preparing the hydrofluoric/nitric acid solution, orange clouds of vapor had us running out the door to escape. We began as titanium jewelers when you could still drive to the chemical supplier and pick up dangerous chemicals in your ...

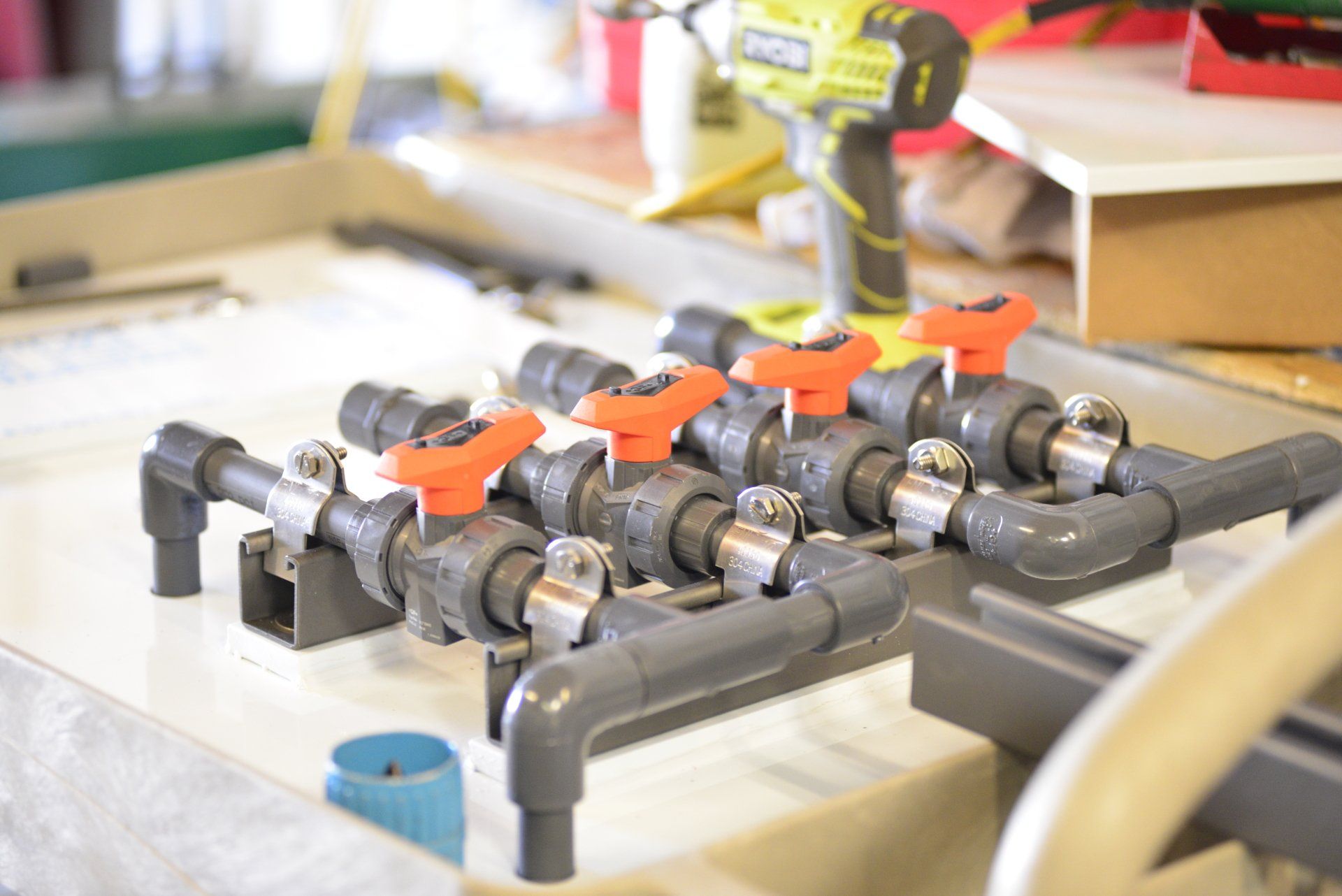

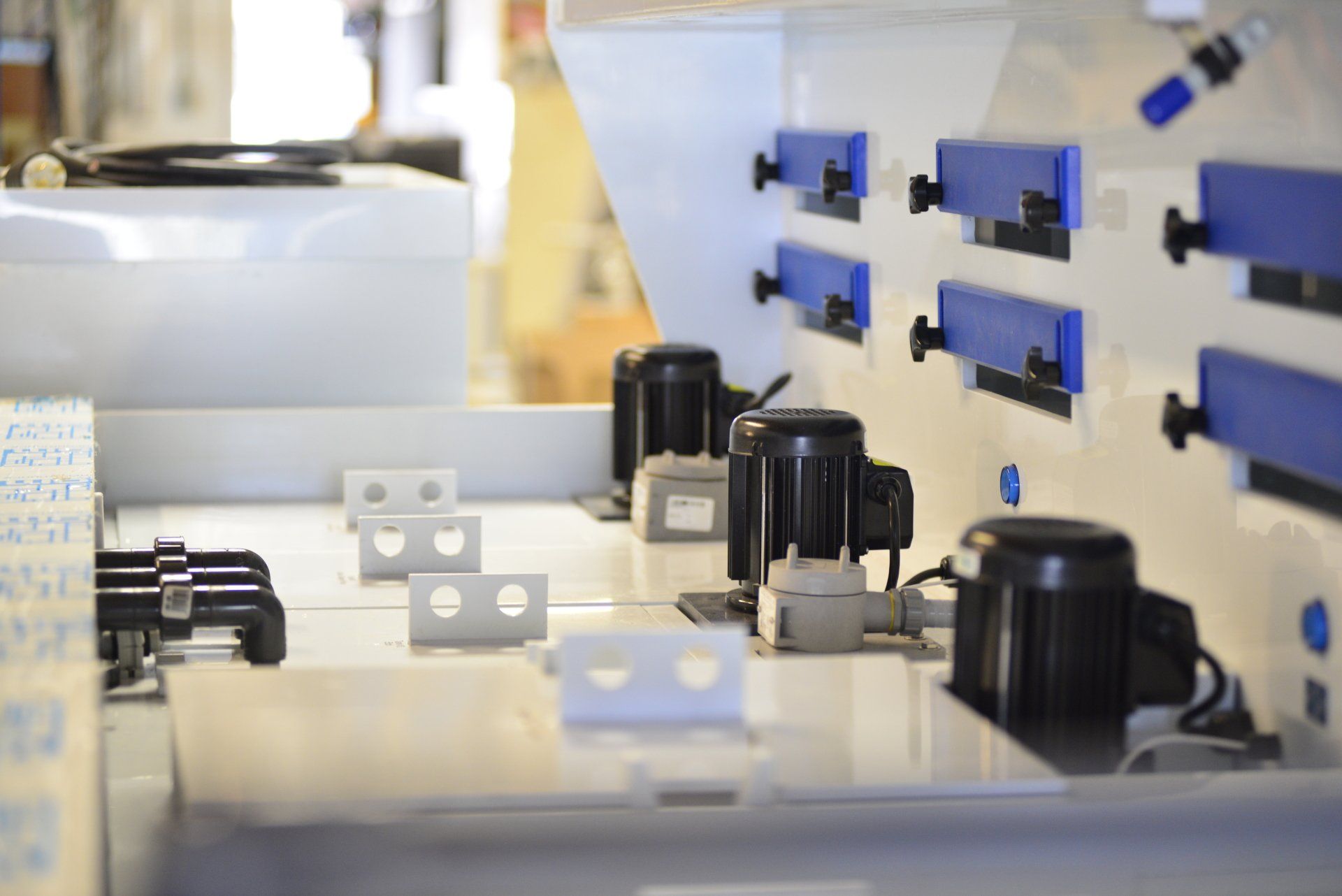

Smaller Titanium Anodizing Systems for Small Parts & Lower Production

Small Titanium Anodizing Console

For customers who need good color repeatability and the ability to switch from one color to another quickly, consider one of our smaller titanium anodizing consoles. Since they use the same programmable remote control and power supply as the larger consoles we build, the color repeatability and functions of the system are very similar, but ...

What are the Benefits to Bringing Anodizing Titanium In-House?

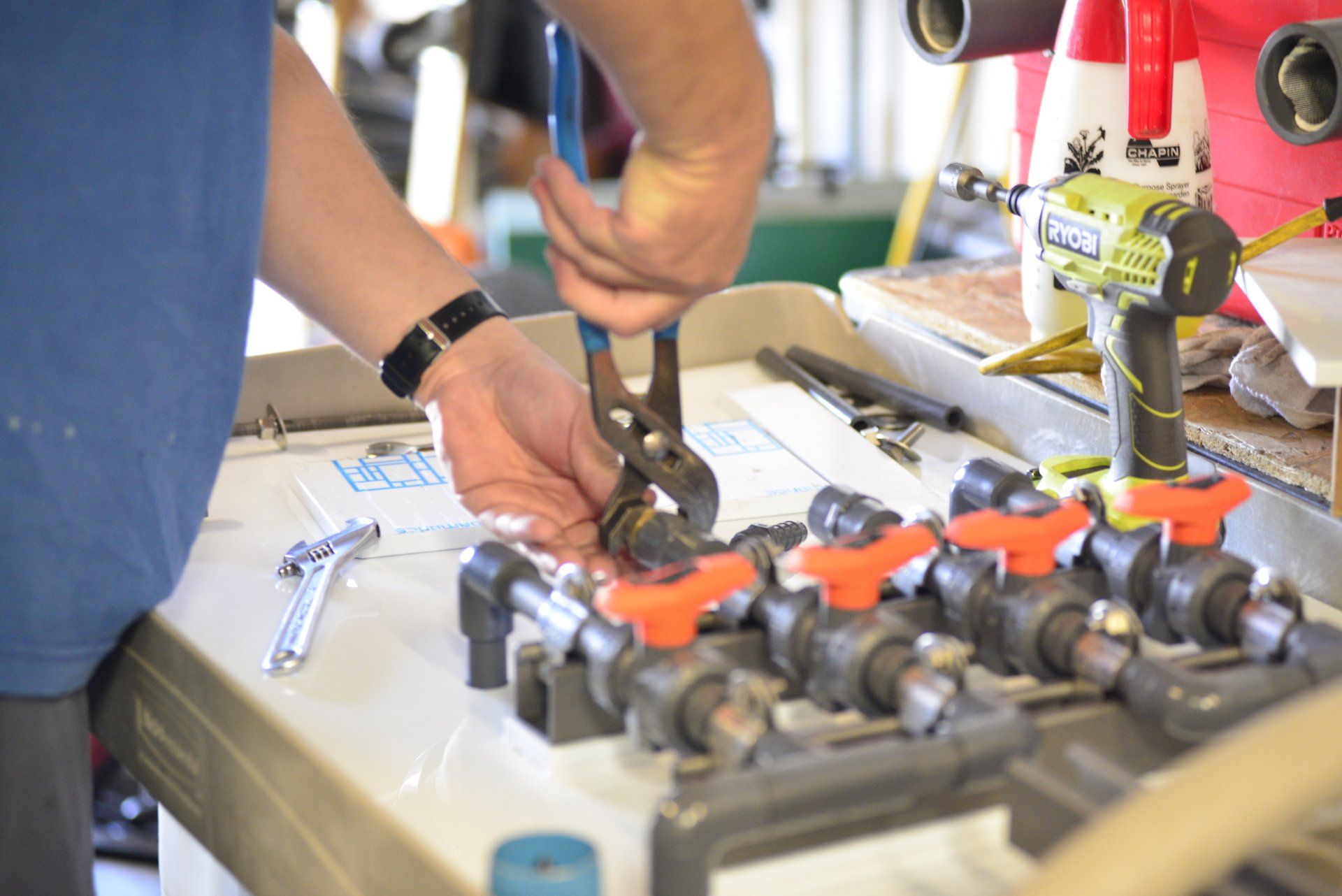

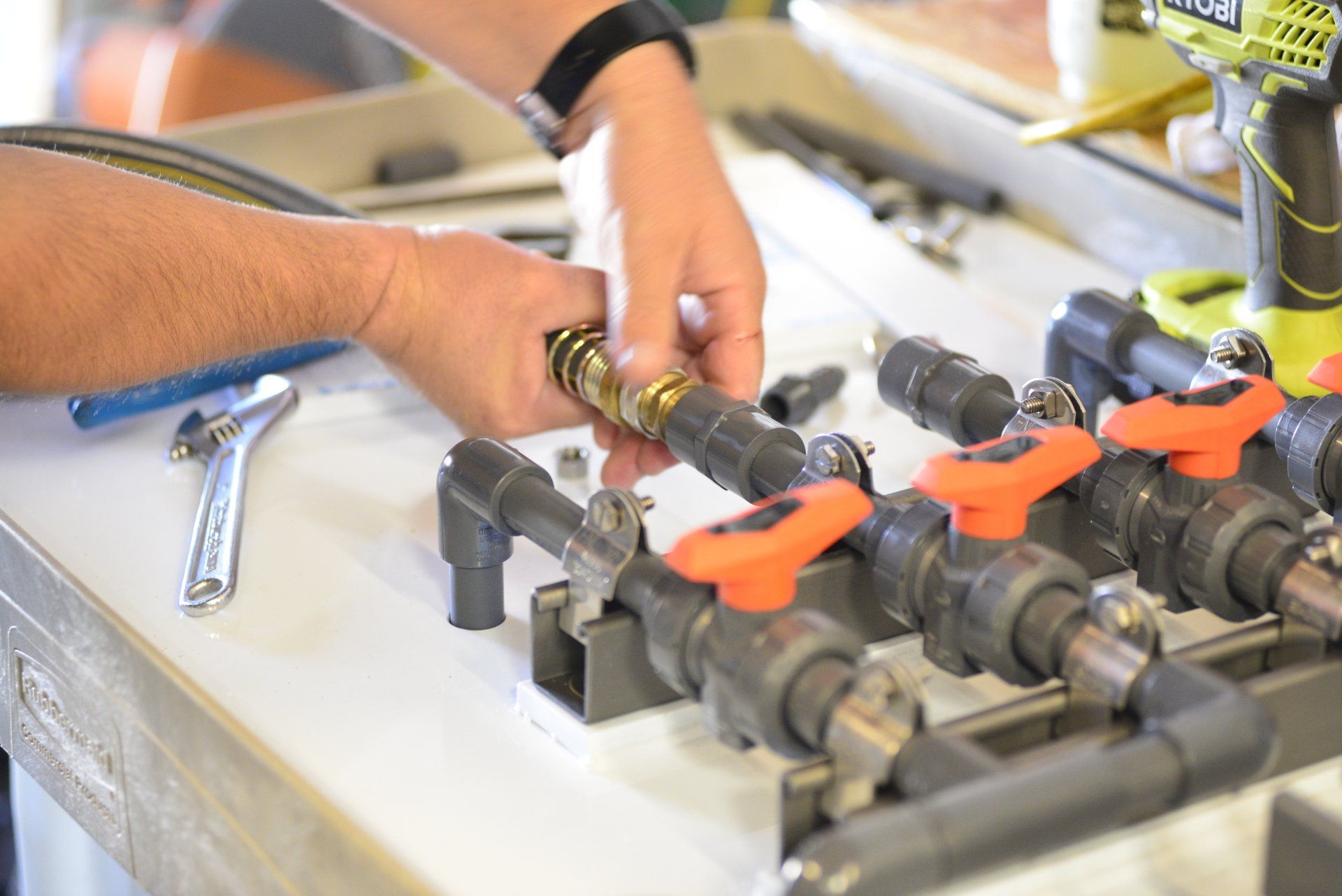

In-sourcing your titanium anodizing

In-sourcing your titanium anodizing needs saves your company money; helps put lead times in your hands rather than someone else’s; improves the quality of the parts and has a quick ROI. Most of our customers never had any experience with chemical processing systems of any kind and have no trouble quickly learning to use and maintain their ...

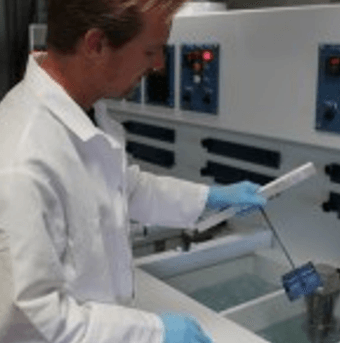

The Medical Anodizing Process

Medical Anodizing

Medical anodizing apparently means different things to different people, usually based upon what aspect of the medical device industry those people work within. Most of our customers in the medical device manufacturing industry refer to medical anodizing when discussing what we would call titanium anodizing, whether it be color titanium anodizing or AMS 2488 ...